WELSA CO.,LTD.

Quality PCB, Flex PCB Manufacturing & PCBA Services

Turnkey & Consigned Manufacturing

Minimum Order

Every PCB project is distinct and varies in size and scope. One client may require a single board for prototyping whereas another may need a few dozen; a small order for one company may be a large order for another. As a result, it’s important to find an assembler that can fulfill an order according to one’s specific need.For example, Welsa specializes in low to medium volume, quick-turn orders – perfect for prototyping new products or smaller production runs whereas other assembly partners may concentrate on quantities over ten thousand pieces.

Components

Evaluate the assembler’s procurement division to determine which vendors provide the components used in the turn-key service. Make sure the company is sourcing parts from certified component suppliers and they are abiding by industry standards for overages and counterfeit material. Are these experts capable of creating an accurate bill-of-materials based on the design file, and, if so, how does the assembler ensure that the PCB is assembled with the exact materials listed on the BOM? It is also helpful to ask about their component substitution policy, in case a part you’ve selected may no longer be available.

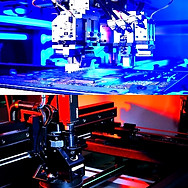

Our Facilities

* Anti Static Floor. Lead-free Process. Nitrogen Process (using Nitrogen generator).

* All products undergo Auto Optical Inspection (AOI) .

* 3 SMT lines, 3 million R/C process/day.

* 6m wave solder line , Thru hole capacity up to 70,000pcs components daily.

* 9m hand solder line.

* 10m assembly line.

* 12m package line.

* Test room.

* Outgoing goods warehouse.

* 250m/Sq 7/24 Temp/Humid control warehouse.

* 600m/Sq incoming goods ware house.

* Mountable minimum chip resistor or capacitor size is 01005 (English) / 0402 (Metric).

* The finest applicable IC pitch is 0.3 mm.

* The smallest applicable ball diameter and pitch of BGA are 0.2mm and 0.4mm respectively.

* Maximum applicable PCB size is L510mm x W400mm. No minimum size limitation.

Quality Management

On receipt of customer's design data and related documentation will proceed with thorough review of all the requirements and transformation of design datum into manufacturing datum via CAM. At the end, a Manufacturing Instructions (MI) comprising of manufacturing datum is devised in accordance

*Formation, Analysis and Control Of Manufacturing Instruction:

We carefully assess and check customer's requirements before proceeding with an acceptance of order so as to be confident that we are capable enough to meet the expected specifications, delivery and other technical and business requests.

*Preliminary Agreement Review:

We experienced professionals assess the Suppliers potential to ensure a portfolio of best in class suppliers is available before final approval. We constantly review and then rank every supplier periodically to ensure a guaranteed best quality materials are provided as per prescribed standards of our requirements.

*Assessment & Inspection of Possible Suppliers:

We have adopted a variety of management procedures and ways to ensure the product delivery meets the customer's expectations through the whole product realization from the Suppliers selection, adequate assessment of WIP and outgoing scrutiny to service the customer. Few examples can be considered in this regards:to our prescribed manufacturing guidelines and technical standards. MI should be verified on formulation by independent engineers and get properly checked and authenticated by QA Engineers before its issuance. The first article inspection will corroborate the drilling and routing datum ahead of issuance.

*Quality Control of Incoming Materials:

We will check all incoming materials prior to moving them to the stockroom. In addition, Additionally,Welsa possesses advanced technology inspection equipment and tools to manage materials to ensure that they are utilized by first-in-first out.

*Process Controls of Fabrication:

We control our complete production process by adoption of various techniques such as Right manufacturing instruction (MI), entire equipment management and maintenance, stringent monitoring of WIP and its inspection along with prescribed working instructions. We strongly believe in satisfying all the customer requirements in semi-products and final products, hence, we use specific inspectionequipments including, the AOI inspection system, well-defined WIP inspection instructions, and a control plan.

*Final Control and Examination:

Our team will ensure that all PCBs after clearance from relative physical tests are passed through the open and short test along with visual inspection. we possess multi-faceted testing equipment comprising of AOI Testing, X-ray inspection, and In-Circuit Testing for finished circuit board assembly.

*Outgoing Inspection and Approval:

We set up a special quality assurance testing function that ensures the products meet the specific customer demands by assessing their requirements via sampling. They must be approved before they are routed to the packaging department. Prior to final shipment, to ensure 100% audit of every shipment for the fabrication, component numbering series, customer's part number, quantity, location details and packing list etc.

*Customer Service:

Welsa strives to meet all customer requirements through its committed, professional, customer service department. We always work hard to provide timely feedback for customers queries and to proactively resolve their problems. In fact, we also work to solve most of the related problems on a customer's site.

- Mountable minimum chip resistor or capacitor size is 01005 (English) / 0402 (Metric).

- The finest applicable IC pitch is 0.3 mm.

- The smallest applicable ball diameter and pitch of BGA are 0.2mm and 0.4mm respectively.

- Maximum applicable PCB size is L510mm x W400mm. No minimum size limitation.

Facilities

- Anti Static Floor. Lead-free Process. Nitrogen Process (using Nitrogen generator).

- All products undergo Auto Optical Inspection (AOI) .

- 3 SMT lines, 3 million R/C process/day.

- 6m wave solder line , Thru hole capacity up to 70,000pcs components daily.

- 9m hand solder line.

- 10m assembly line.

- 12m package line.

Production Lead-Time

The delivery time for the assembly of your printed circuit boards depends on the number of components to be assembled. Assembly will start on the day on which all the materials that are necessary (components, including the required surplus amounts, printed circuit boards, and stencil) have arrived.

Sum of the components = sum of the SMD and THT components x the number of printed circuit boards to

be assembled.

Please note: The time that we need to assemble the printed circuit board is to be added to the Production time of the printed circuit board. Therefore, please order the components required for assembly in good time.

Components

We process components supplied by you and components purchased for you. If you wish to assemble particular components yourself, Please note this in the corresponding BOM.

The components that you supply must be delivered in a well-packed condition and be clearly marked and labeled.

Please use the component designations that are also entered on your bill of material (BOM).

For components to be ordered for you, we require suitable ordering information such as the supplier and order number. Please ensure that your components are delivered in the stipulated machine-compatible production packaging, otherwise, we will be unable to accept them.

BOM - Bill of Materials

Notes

Assembly can start only after we have received all the required components.

When selecting your components, please pay attention to availability and delivery times.

We do not expect to lose a significant number of components, but to be safe we prefer to receive slightly more components (10% suggested) than required so as to avoid any delays to delivery should any loss occur.

The excess amount must be in the same section as the components that are actually required. In the case of active components, the excess amount depends on their type of housing and the unit price of the component. Ideally, we would like to have at least one or two extra components.

All components must be supplied in moisture-proof and ESD compliant packaging. All unused components will be returned to you.

Contact Us for RFQ or any inquiry!

E-mail: sale@welsa.com

Updated : 2022

SMT Process Capability

In order to avoid errors and delays during the assembly, we require your BOM, a Pick&Place file and a layout diagram in the correct format.

Please ensure that the Pick&Place data are saved and sent as a .txt file. It is essential to provide all the coordinates in millimeters.